#004

POLYMETAC™ meets

SATOSHI YOSHIIZUMI

「deposition」

- TAKT PROJECT

- SATOSHI YOSHIIZUMI

The TAKT PROJECT has explored various possibilities of products, such as acrylic lighting fixtures free of electronic printed boards and plastic chairs that users can dye in any color they wish.

In this project, they worked on a technology for integrating metal with resin.

Its aim was to create a new material from an existing material with the use of POLYMETAC™.

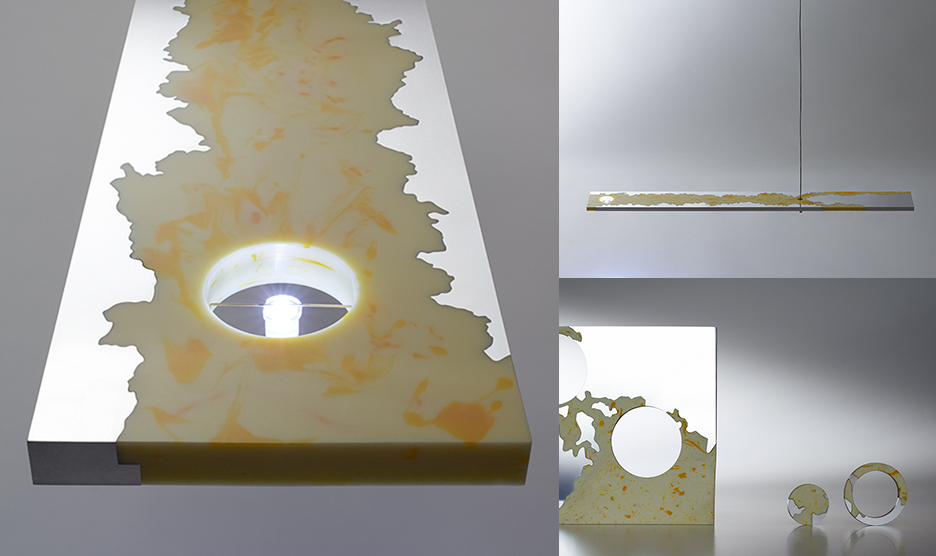

A plate created by integrating metal with resin

In this project, we started by addressing questions as to essentially what the material was and what made the two terms raw material

and ingredient different, before developing a product from a material produced by Mitsui Chemicals. In our philosophical exploration, we reached an answer, which is that the material has power that induces creativity. Take wood, for example. Those who have encountered this material have created many different items by cutting, planing and otherwise processing it. This is a result of the wood, as a material, inducing people to produce these items. Many of the materials dealt with by Mitsui Chemicals have been created from existing materials for the purpose of producing something new. By determining a concept of processing an existing material to produce a new material, we attempted to create a material that makes people want to create something from it at a glance. To realize this concept, we used POLYMETAC™ technology that bonds or joins to integrate metals and resins. With the help of the staff in the Hybrid Materials Department at the New Products Development Laboratory of Mitsui Chemicals, we took advantage of this technology to produce a new material that integrates plastics and aluminum.

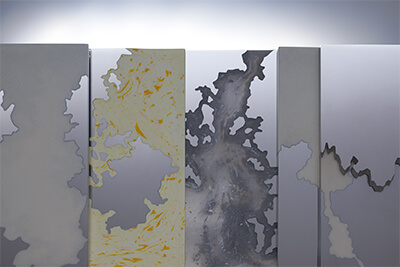

When we work out a design with the use of wood or any other natural material, we usually start by observing its color, grain and other features. This material has a range of looks in the process of injecting a resin into the metal, and it has different material characteristics that are distributed unevenly. Although it is an industrial material, it inspires us to observe its features. As examples of products that take advantage of these features, we produce a punched ring and a lighting product. The integration between the metal and the resin in a tiny ring product and the harmony in the textures of the two different materials make a fresh impression. Depending on the trimming of the plate material, it is possible to think of this material as a substrate by applying electricity to the aluminum part. The process in which the plate turns into an illuminator blurs the boundaries between materials and products and causes us to forget the concept of components.

The creation of a new material means the creation of a new possibility. We hope that many designers will discover the potential of this material and technology.

About the material

Today, there are needs to reduce weight and the number of manufacturing processes in the automotive sector and the electronics sector, and the shift to multi-material integration is gathering momentum.

Mitsui Chemicals’ POLYMETAC™ is a metal-resin integration technology for strongly bonding various combinations of metals and resins in a manner that was formerly impossible. It is Mitsui Chemicals’ latest solution that fulfills the needs for the reduction of both weight and manufacturing processes.

Formerly, to join a metal with a resin, it was necessary to use an adhesive or joining components such as screws.

However, the practical implementation of multi-material integration was technically and operationally challenging. For example, it was necessary to select an optimal adhesive on a case-by-case basis, there was unevenness in adhesion strength, and it was necessary to perform maintenance work frequently because of the loosening of screws.

POLYMETAC™ involves the special treatment of a metal to form fine pores of nanometer to micrometer size, and a resin is then poured into them to achieve physically strong adhesion and connection.

By injection molding and casting, it is possible to produce integrated components with a high level of adhesion strength without using adhesive.

Even when integrating materials that are incompatible with injection molding or casting, it is possible to connect different metal components with resin components with the POLYMETAC™ treatment and the use of adhesives. This results in greater stability in terms of adhesion strength than conventional adhesion. It helps to reduce instability or the age deterioration of components and improve rigidity.

- TAKT PROJECT / Satoshi Yoshiizumi principal

- Co-founded TAKT PROJECT Inc.in 2013. Carries out various projects for Creating Other Possibilities under the slogan of DESIGN THINK+DO TANK. Voluntarily or in response to invitations, exhibits experimental works as well as works ordered by clients at the Salone del Mobile and other events and has won a Red Dot Design Award, Good Design Awards and many more.

- Concept+Design/Satoshi Yoshiizumi

- Design/Takeshi Miyazaki

COMMENT

New Products

Development

Laboratory,

Mitsui Chemicals

In this project, the TAKT PROJECT provided us with a proposal for a design that can only be undertaken with POLYMETAC™ and that helps viewers understand POLYMETAC™’s integration mechanism.

Traditionally, we engaged in component development with a focus on weight reduction and the improvement of the exterior appearance, and we found the concept of the material that induces creativity quite innovative. It was a moment when we learned that depending on the creator’s idea, conductivity, a shifted center of gravity and other new functions could be added to the POLYMETAC™, and new value could be created.

The products are brilliantly designed. They provide an impression of wonder in terms of the integration between the metal and the resin, even on us, although we are aware of the mechanism behind the integration. We hope that many people will touch the POLYMETAC™ so that we can discover new value beyond our imagination together.

We would like to offer our thanks not only to the TAKT PROJECT, but also to Sagamikokisyo Inc. and to Shin-ei sha Co., Ltd. for cooperating with production, and to Mr. Masayuki Hayashi for the outstanding photography.